The author presents some of the safety and tactical considerations firefighters must address when aluminum composite panels are proposed for high buildings in their districts.

C omposite panel cladding has been around for a long time, and most of us probably have seen it in its simplest form—used as a replacement for clapboard siding on domestic structures. As an alternative to traditional siding, it is low maintenance and may even have higher thermal properties than traditional timber. It generally appears as polyvinyl chloride (PVC) or aluminum house siding. Although it is not specifically combustible, many of us have experienced the mess these products can make when exposed to fire. EPS Raw Material

Technological development of these materials in the 1990s and 2000s has expanded the applications for composite cladding beyond that of simple clapboard siding. Composite panels have existed in industry for many years and are used in many other areas such as for signage and decorative finishes. When used in signage or for shop fitting, the composite panels range up to around one-quarter-inch thick. Each panel is usually comprised of aluminum, copper, or zinc finishes on the face side, which, in turn, sandwiches a polymer-based material internally. The approximate thickness of the metal outer skin may be 0.019 inch or around 24 gauge; the polymer component would be approximately 5⁄32 inch. This allows the sheet that is created to be formed or rolled and minimizes bulk metal costs and keeps weight at a minimum while providing good thermal characteristics (photo 1).

(1) An aluminum composite panel may be formed into any shape vertically and gives a modern look to new buildings or revitalizes older structures. This close-up image shows the shiny panel installed at the entrance of an auto dealership. (Photo by Greg Havel.)

More recently, however, there has been a great expansion of the product’s use like its clapboard cousin in the construction industry—as a cladding on the external walls of buildings. This has been the case overseas in many Type 1 high-rise structures. The predominant type is aluminum composite panel (ACP), which, as is true of any manufactured product, varies greatly in price. This difference in price is reflected in the quality of the materials and the product’s fundamental performance under fire conditions.

You may have seen footage of recent high-rise fires in Dubai, in the United Arab Emirates, which showed advancing fire external to the building over multiple floors. Similar fires have occurred in China, France, and Australia; all were related to the use of composite panel cladding.

(2) Combustible aluminum composite cladding on the Forté building in Melbourne, Australia. (Photo by author.)

The key issue is the material used as the filling of the “sandwich” between the layers of aluminum. Fire-rated panels manufactured to a high standard use a polyethylene/mineral fiber core; inferior products from a fire performance perspective contain polyethylene polymer fiber only.

(3) The Forté building during the cladding fire event in 2014. A cigarette discarded on the balcony ignited the garden furniture. Because this cladding is used extensively globally, firefighters should consider whether their department has the resources to handle an event of this dimension. In this context, overreliance on inbuilt fire systems (sprinklers and so on) may be to our detriment because the building and its systems are designed to contain fires occurring within the building. (Photo by Wade Savage; used with permission.)

At an incident that occurred in Australia in late 2014 (photos 2-3), a 21-story apartment block was involved in fire as a result of a discarded cigarette left on garden furniture on an eighth-floor balcony. The developing fire caught the exposure of the wall paneling, and the fire moved externally over 13 floors in 15 minutes (it stopped at the top floor) and extended to exposures on each balcony. The dropping down of flaming material caused balcony exposures down to the sixth floor of the building to become involved as well. Fortunately, the building’s sprinkler system performed beyond its design standard and the efforts of firefighters prevented the fire from taking hold of the structure. On investigation post fire, the wall product was found to be a cheaper imported product that did not meet the required fire resistance. When the product was laboratory tested by the Commonwealth Scientific and Industrial Research Organisation (CSIRO), Australia’s peak scientific body, the experiment had to be abandoned after 90 seconds because of high fire growth and smoke output from the sample.

In this case, the municipal authority supported by the local fire agency acted to prevent a reoccurrence of this event. A number of tribunals were held along with the subsequent appeals process. The outcome was successfully imposed orders for the building to be stripped of the product in its entirety and to be reclad in a noncombustible material. Agents representing the building’s stakeholders presented alternatives to removing the panels, such as external wall-drenching systems. In an excellent example of leadership from our industry, the fire agency opposed successfully those alternatives based on many factors, including hidden fire travel on the rear of the fixed panel.1-2

Not all situations are met with success. Attempts to prevent ACP use in other jurisdictions, although laudable, have not been as successful.

Australia, unlike the United States, has a national building code. The Australian code incorporates the requirements of fire performance. The code is then referenced by individual states that reflect the code to a varying degree in state legislation and regulations.

The code prohibits the use of combustible cladding in class A buildings (U.S. equivalent, Type 1); however, in Australia there was an initial lack of full-scale façade testing, and some suppliers of the paneling provide a product that has merely achieved a level of qualitative testing without any large-scale fire testing.3 Less scrupulous providers and developers circumvent codes in many ways when applying terms such as “combustibility” and a “deemed to satisfy” arrangement. It’s not all bad. Many reputable manufacturers have small fire scale test data that illustrate a product’s level of noncombustibility in standard fire tests. Obviously, more needs to be done. It appears that inferior products with less than minimal performance have found their way into the global marketplace.

Overall, this may be a case of materials technology moving at a pace that outstrips code definitions, a situation that supports the application of specific codes such as National Fire Protection Association (NFPA) 285, Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Non-Load-Bearing Wall Assemblies Containing Combustible Components, that define test criteria for external wall assemblies.4

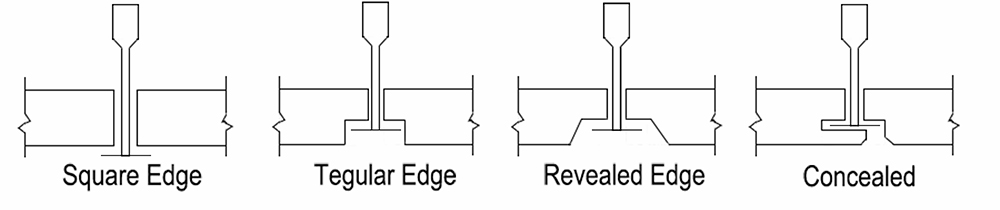

The issue of ACP extends beyond its fire resistive qualities. Installation of the panel as a cladding system heavily influences the performance of the product under fire conditions. Primarily, there are two methods of installation: direct stick and cassette.

A weather barrier is applied to the external building frame. A metal furring channel is then attached to the frame of the structure, and double-sided tape is then applied to the channel. The composite panel with unfinished edges is attached to the building with the tape. Vertical joints at each panel are sealed and supported from behind by a Styrofoam® strip glued to the frame (photo 4).

(4) A cross-section of panels installed using the Direct Stick method. (Photo by author.)

This method exposes the inner section of the panel to flame impingement from an external source. The Styrofoam also allows flame to propagate further along the panel edge and to the rear side. The adhesive may fail under fire conditions, and the panel may be released from the structure, compounding issues.

This method is like the direct stick method in that a weather membrane and a furring channel are applied to the frame. The primary differences are that each panel has its edges bent internally at 90° and a bracket is attached. The bracket is screwed to the channel at the structure. The joint is then sealed with a mastic type product (photo 5).

(5) A cross-section of panels installed using the Cassette method. Note how the panel’s edges are bent 90° like an inverted “U” and that each panel is positively secured by a bracket and screw. This is a much more secure method than the Direct Stick. However, the system is still prone to unchecked fire travel in the void space at the rear of the panels. Fire stopping is essential when using either method. (Photo by author.)

The advantages of this method are twofold: (1) The internal edges of each panel are protected from external flame sources; and (2) the panel is mechanically attached to the building by screws, minimizing the likelihood of its coming away from the building during a fire.

From a tactical perspective, the primary concern is the size of the response needed to manage a fire of this type in a tall building because of the number of floors affected simultaneously. A resource-intensive commitment of the fire crews is needed for the following:

For firefighters who work in building and code enforcement, ensure that if ACP is specified that it meets and is tested to your standards and that the material is the same as what was stipulated. Also ensure that break/stop points are specified on both sides of the external skin to reduce the risk of unchecked fire progression.

Fire stopping/barriers between floors, fire modeling, and analysis are not well-established for this product. Do not accept alternative solutions without full-scale testing or risk assessment, such as that that may be available from Underwriters Laboratories (UL) standards. In North America, aspects of the International Building Code (IBC) can make interpretation of the use of ACPs difficult and may lead to incorrect application of the product. The presence of firefighters and fire protection engineers on standards technical panels such as those of UL is essential.

Obviously, nothing is fireproof, and ACP products of the highest standard still contain polymer and, therefore, will still decompose when heated. The critical issue is that identifying an inferior product on a constructed building is difficult at best. In Australia, it is not known how many buildings in the country are clad with an inferior product; government estimates are in the thousands. Many other countries are now only beginning to experience the problem. What’s in your backyard, America?

At the time I was researching this article, the Grenfell Tower fire in the United Kingdom had not yet occurred. As I write this section, my television is showing firefighters searching the burned-out hulk of the 24-floor, 120-apartment residential building. It was a conflagration in the truest sense of the word. As days pass, the displaced families’ hopes of finding loved ones dwindle as the death toll steadily rises.

The fire tested the 5,000-plus-member London Fire Brigade, with more than 40 apparatus and 200 firefighters valiantly trying to stop the fast-moving fire. The firefighting effort took days, and concerns of structural integrity were pushing resources to concentrate on attack within the range of aerial apparatus while the uppermost floors exhausted the available fuel, eventually burning out.

Even prior to the last apparatus leaving the scene, the investigative process had begun and the scale of the event will make it the subject of intense investigation for some time. It appears that the fire initially began in a failed appliance in a fourth-floor apartment. Sadly, reports indicate that the external cladding used (nonfire resistive polyethylene core composite panel) in a recent renovation on the 43-year-old building contributed heavily to the speed and spread of fire throughout the structure.

Video footage from early in the incident shows fire moving quickly across the outside of the city-owned building. Since it is constructed of steel-reinforced concrete, it can only be deduced that the composite cladding is supporting this. Closer inspection shows vertical and horizontal flame travel corresponding with panel location. What is not known at this stage is if any insulation product was fitted at the rear of the cladding to improve the building’s thermal properties. Drop down of burning paneling is evident during the fire; postincident footage also illustrates the sheer quantity of drop down into the surrounding area. Fortunately, secondary fires and exposure risk were minimal.

Apart from the inherent fire risk of the cladding on Grenfell Tower, some specific questions are raised:

These questions, based on hard lessons learned in battle, have been asked in various contexts time and again by those before us. The Dunns, Brannigans, and Mittendorfs of the world have written numerous times on the dangers of building renovations and modifications and a change of use and how they can affect building performance and occupant safety during fire conditions.

The refurbishment of Grenfell Tower undertaken in 2016 involved modernizing utilities internally and improving the visual amenity of the building externally to gentrify the area. Although investigations are ongoing, it has been implied that the cladding used carried no fire rating and the difference in upgrading to a fire resistive product would have been approximately $6,500 extra on the $11 million project.

Download a PDF of the postincident report of the Lacrosse fire by Metropolitan Fire Brigades (Melbourne, Australia) at http://www.mfb.vic.gov.au/News/Publications/Reports.html /.

You can find the Fire Protection Association of Australia media release with appeal determination link here: http://www.fpaa.com.au/news/news/ 2017/01 /bab-lacrosse-determination.aspx .

An excellent video presentation (including fire development animation) of the postincident analysis also by the Metropolitan Fire Brigades (Melbourne, Australia) is at https://www.youtube.com/watch?v=dH1YiB3767k /.

Philip Paff, AFSM, MIFireE, CFO, is a 22-year member of and a captain with Fire and Rescue Queensland and is assigned to Station 48. He is a member of Australia TF 1 USAR. He has a bachelor’s degree in emergency service operations. Paff was awarded the Australian Fire Service Medal for his contribution to rescue.

1. Fire Protection Association of Australia 2017, “Safety the first consideration for lacrosse residents.” Viewed 1 February 2017, http://www.fpaa.com.au/news/news/2017/01/bab-lacrosse-determination.aspx

2. Metropolitan Fire Brigades 2014, “Post Incident analysis–lacrosse docklands” viewed on 29 December 2016, http://www.mfb.vic.gov.au/News/Publications/Reports.html

3. National Fire Protection Association Standard 2014, Fire Hazards of Exterior Wall Assemblies Containing Combustible Components.

4. National Fire Protection Association 2012 “NFPA 285: Standard fire test method for evaluation of fire propagation characteristics of exterior non-load-bearing wall assemblies containing combustible components.”

http://www.fireengineering.com/articles/2017/07/construction-concerns-combustible-cladding.html

http://www.fireengineering.com/articles/pt/2017/07/flammable-cladding-used-in-us-buildings.html

http://www.fireengineering.com/articles/2017/06/after-the-grenfell-fire-brits-order-evacuation-of-other-high-rise-cladding-buildings.html

Stay in the know with the latest content, features, and training from the largest online firefighting community.

Please check your spam folder and any email filters, in the event that the email gets blocked.

Glass Wool Properties Stay informed about daily FireEngineering news, podcasts, training videos, webcasts, commentary, and exclusive articles about FireEngineering by signing up.